Disinfect seawater intakes, pre treatment, RO membranes and finished stock from one Ultra-Pure system, without creating disinfection by products (DBP).

Scotmas Bravo Ultra-Pure (BUP) is our unique, patented Chlorine Dioxide generation system, designed to produce the purest Chlorine Dioxide solution.

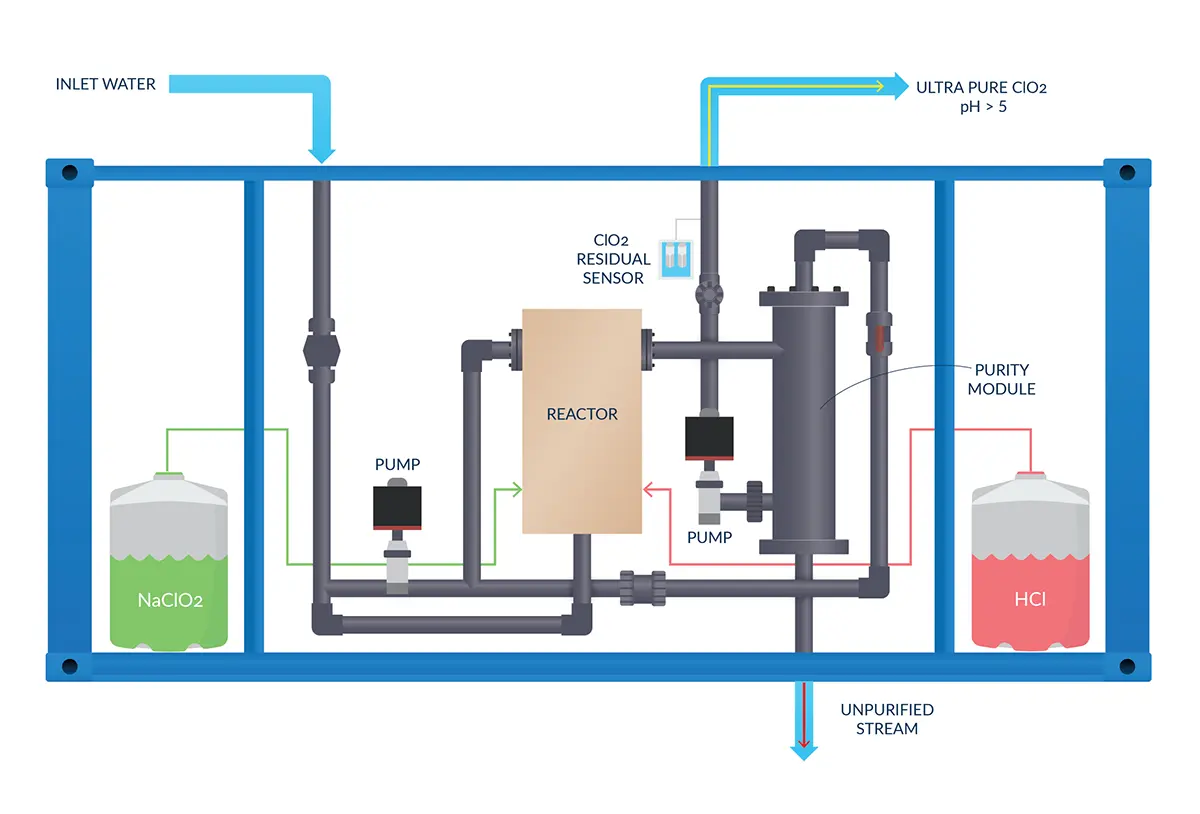

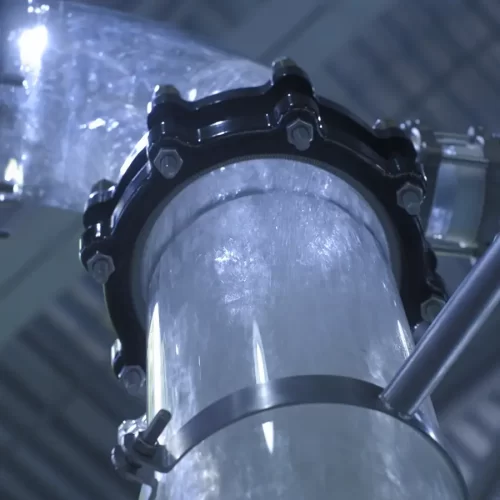

A physical barrier prevents impurities and disinfection by products (DBP) from reaching the finished water, leaving a solution which has been independently tested to be 99.7% pure.

The Scotmas Bravo Ultra-Pure Generation and Dosing System is a technology patented, WIMES (Water Industry Mechanical and Electrical Specifications) compliant system which introduces a stream of ultrapure Chlorine Dioxide solution (100% ClO2) into the treated water stream, without any other generation byproducts (GBP) from the reactor.

Chlorine Dioxide is produced in small volumes as required by the demand from the water being treated – no storage of Chlorine Dioxide solution is required or performed.

For SWRO, Scotmas Bravo Ultra-Pure separation technologies remove and recycle excess acids and reaction by-products from the Chlorine Dioxide stream, provide the opportunity to maintain desalination membrane osmotic pressure at design levels, keep energy consumption constant, increase membrane longevity and significantly reduce CIP cleaning.